The old ways of warehousing are ripe for change. And this change is already well underway, thanks to the incredible eruption of AI and automation in recent years.

With labour becoming harder to find, customer expectations becoming sky-high, and little to no room for error or delays, embracing this new tech is almost inevitable now for every business, big or small.

The old ways—manual stock checks, paper logs, repetitive labour, spreadsheets, paper trails, guesswork—just can’t keep up anymore.

But what exactly does AI and automation bring to the table in the warehousing world?

In this post, let’s take a look at how AI and automation are changing warehousing, from the moment a product hits the shelf to the second an invoice gets sent. Real tools, real impact, and simple ideas you can put to work.

Smart inventory management

Let’s start with the backbone of any warehouse: inventory. If you’re still relying on manual counts or waiting for stockouts to tell you something’s off, you’re leaving money on the table.

AI can take care of the grunt work here. With an automation-focused ERP software, you can easily track inventory in real time, predict demand based on sales trends, seasonality, and other factors. It flags anomalies before they become problems. Think fewer stockouts, less overstock, and no more last-minute scrambles.

You can also bring in automation tools—like drones or shelf-scanning robots—that do routine cycle counts without breaking a sweat (or taking up your team’s time). That means your staff can focus on higher-value tasks instead of walking aisles with clipboards.

Case in point: Logistics providers like PACK & SEND New Zealand are increasingly adopting smart inventory workflows to improve speed and accuracy across their fulfilment networks.

Automated picking and packing

Picking and packing are where speed, accuracy, and labour costs collide. And if your team is still handling everything by hand, you’re probably feeling the squeeze.

AI-powered vision systems can identify, sort, and route items with precision. Combine that with robotic arms or Autonomous Mobile Robots (AMRs), and you’ve got a picking operation that doesn’t take breaks—or make mistakes.

For teams that aren’t ready for full robotics, there are hybrid solutions. Voice-guided or AR-assisted picking helps workers move faster with fewer errors. This is a great way to empower your staff to do more in less time without changing your whole setup.

Start by analysing your order history. AI can group frequently ordered items together, optimising pick paths and cutting down travel time. That one change can shave hours off your daily workflow.

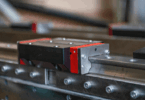

Warehouse navigation and robotics

Getting products from point A to B inside a warehouse might seem simple—until you realise how much time your team spends just walking around.

That’s where robots come in.

Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) can zip around the warehouse, picking up, dropping off, and sorting goods without bumping into people or each other. Powered by AI, these machines plan the most efficient routes in real time, adjusting on the fly based on traffic or new priorities.

And good news: you don’t need to run a mega-warehouse to use them.

Here are a few AMRs that work well for smaller warehouses and growing businesses:

- Locus Robotics: Ideal for eCommerce and 3PLs; easily integrates with most WMS systems and scales with demand.

- Fetch Robotics (now Zebra Technologies): Offers cloud-based AMRs for material transport with quick deployment.

- Geek+ P-series: Compact and cost-effective AMRs great for tight warehouse layouts.

- MiR (Mobile Industrial Robots): Flexible mobile robots that don’t require major changes to your warehouse setup.

Some (like Locus) even come with leasing or robotics-as-a-service (RaaS) options, making them easier on the budget. So if you’re not ready for a full fleet of robots, consider leasing one or two AMRs for your highest-traffic zones. Many vendors offer trial setups that integrate with your current systems.

AI-powered order fulfilment

Order fulfilment is where everything comes together—and where small inefficiencies quickly turn into big costs. The good news? AI thrives in this part of the process, too.

AI tools can analyse your order patterns and automatically group similar orders for batch processing. That means less travel time, smarter packing, and faster throughput. It can also recommend optimal packaging for each order to minimise waste and shipping costs.

Another perk? AI can learn from past delays or bottlenecks and tweak fulfilment rules to avoid them next time. For example, it might prioritise items that are more likely to ship together or reroute orders to the fastest-fulfilling warehouse.

Here are two smart tools that help smaller operations get started with AI-powered fulfilment:

- ShipHero: Combines order management, warehouse operations, and smart picking logic in one platform. It’s a great all-in-one tool for eCommerce brands and 3PLs.

- Logiwa WMS: Designed for high-volume small businesses and growing warehouses, Logiwa uses AI to optimise picking, packing, and shipping with real-time updates and automation baked in.

Real-time monitoring and predictive maintenance

Warehouse downtime is a silent killer. A stuck conveyor or a broken forklift might seem like a small hiccup, but it can ripple across your entire operation.

That’s where real-time monitoring and predictive maintenance come in.

With IoT sensors and AI working together, you can track the health of your equipment 24/7. These systems detect wear and tear early, sometimes before your team even notices a problem. They also learn from past breakdowns to predict what might fail next, and when.

Instead of waiting for something to break, you fix it on your terms. That means fewer emergency repairs, better uptime, and smoother workflows overall.

For small and mid-sized warehouses, here are a couple of tools worth checking out:

- MaintainX: A mobile-first CMMS (computerised maintenance management system) with real-time alerts, work orders, and asset tracking. Simple enough for small teams, powerful enough to scale.

- UpKeep: Offers predictive analytics and maintenance automation for equipment-heavy operations. Easy to set up and integrates with IoT sensors and warehouse systems.

If nothing else, start logging equipment issues in a simple app. Even without sensors, a basic history helps spot patterns you can act on.

Smart invoicing and billing automation

Billing is one of those tasks that should be simple, but rarely is. Manual data entry, paper receipts, missing records…it all adds up to delays, errors, and headaches.

Automation fixes that. With AI-powered invoicing tools, you can generate, review, and send invoices automatically, based on real-time data from your warehouse, orders, and inventory systems. No more chasing numbers or manually matching POs.

AI can also scan physical documents using OCR (optical character recognition) and pull out key info instantly. And if you’ve got different clients, pricing models, or terms? Rules-based automation handles it all.

Here are two tools small businesses love for automated invoicing:

- Zoho Invoice: A lightweight but powerful tool for automating recurring invoices, tracking payments, and syncing with inventory.

- Stampli: An AI-driven AP (accounts payable) platform that helps small to mid-sized teams speed up invoice processing, reduce manual work, and flag inconsistencies before they become issues.

Automate one recurring invoice process this week. You’ll realise it can free up hours you didn’t know you were wasting.

Data-driven decision-making

Your warehouse generates a mountain of data every day—orders, inventory levels, fulfilment times, equipment status. But if that data just sits in spreadsheets, it’s not helping you grow.

AI turns that raw info into insights you can actually use.

With the right tools, you can get real-time dashboards showing what’s working, what’s lagging, and where you’re burning time or money. You can forecast demand more accurately, plan labour needs better, and even uncover trends you didn’t know were there.

And it’s not just for the big guys. Plenty of AI-powered tools are designed specifically for small to mid-sized operations.

A couple of solid options:

- Zoho Analytics: Offers AI-driven insights and predictive analytics, helping small businesses make informed decisions based on their warehouse data.

- Microsoft Power BI: Affordable and powerful, with AI visualisations and predictive analytics that can plug into your inventory, WMS, and accounting systems.

Start small. Set up a basic dashboard that tracks just three things: order accuracy, fulfilment time, and stockouts. It’s a small step with big visibility.

Wrapping up

AI and automation aren’t just for the Amazons of the world. Today, even small and mid-sized warehouses can use smart tools to work faster, reduce errors, and stay competitive.

From inventory to invoicing, every part of your operation has something to gain—whether it’s more visibility, fewer manual tasks, or just getting ahead of the next bottleneck.

The key isn’t to do it all at once. It’s to start small, solve one pain point, and build from there. Because once you see the impact, the next steps usually make themselves clear.

So, the bottom line: AI and automation won’t replace your warehouse team—but they’ll make them way more effective. Also, the tech is moving fast. Even if you’re not ready to invest today, stay curious. Keep a list of tools that could help your ops in the next 6–12 months. When the time’s right, you’ll already be ahead of the curve.